Design Course

Sheet Metal

Fabrication Technology in Product Design

by

Fewer parts make a good assembly. While designing products, it is essential to conduct an analysis of product structure. It will be helpful and save money to eliminate surplus parts. One can combine parts by functionality by removing redundancy.

An assembly has to store, sorting, position, adjust and join operations. Lesser the components better are control over quality and efficiency. This is where design for manufacturing and assembly comes into the picture. Understanding DFMA and following using simple principles will go a long way in the outcome of a good product. In some products cost of assembly and overheads may exceed the bill of materials and production costs. In such cases, the cost benefits are substantial if the product is designed keeping in mind assembly easiness.

Design for Excellence by James G. Bralla, Mcgraw-Hillan is an extremely helpful book.

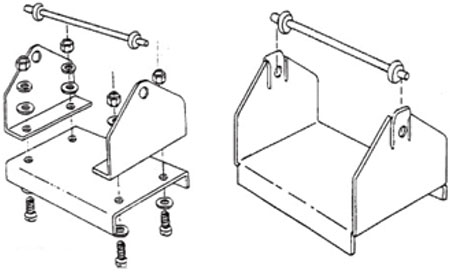

Reduce the Part Count

The design efficiency is increased by over 30 %.

(Image source)

The design on the left has 24 parts while on the right has 2 parts. The improved design has also reduced the manufacturing processes to the barest minimum and has just one assembly step.

The two main factors that affect the assembly cost of a product are the number of parts to be assembled and the ease with which the parts can be handled. A product with fewer parts will cost less to assemble. Thus, the best method to reduce assembly costs is to reduce the number of parts in the assembly.

The part reduction can be accomplished by eliminating redundant parts, combining two or more parts into one. For example, screws and washers may be eliminated by adapting press or snap-fits to join two components. Choosing the right type of fasteners for the right purpose and minimizing the variety of fasteners also help in reducing the assembly time and cost.

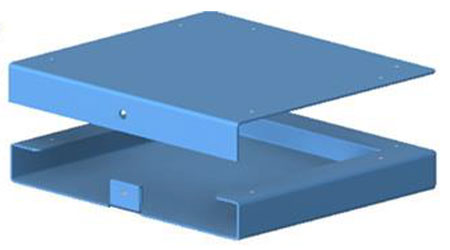

Simplify Assembly

Locating a part to the correct position takes time and effort. In this example, a snap-fit is incorporated to locate and align the top cover with the bottom cover. This eliminates a screw fastener at the indented area and minimizes the total number of fasteners.

Boothroyd & Dewhurst and Lucas Methodologies suggest categorizing parts as “A” essential and “B” Target for designing out. Where design efficiency is ( A/A+B) X 100 %. In sheet metal assemblies, Parts may be considered as ‘A” category and fasteners may be considered as “B” category. But within an assembly, some parts may become “B” as well-targeted for designing out.

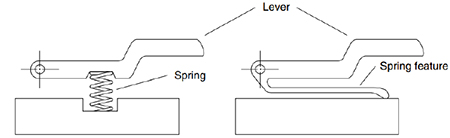

Integrate

Most often it is possible to integrate functions of two parts into one. Understanding of material properties comes to good use.

By incorporating the spring function in the lever, the need for a separate coiled spring is eliminated.

From James G. Bralla. Design for excellence, Mcgraw-Hill

(Image source)

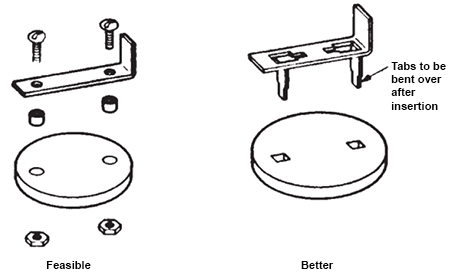

Innovate

From James G. Bralla. Design for excellence, Mcgraw-Hill

(Image source)

Consider the use of snap fits. Screw-type and other separate fasteners can be replaced with integral snap-fit elements, tabs, or catches. These can be incorporated in many parts such as guides, bearings, covers, etc.

Polarize

(Image source)

One of the phenomenons one comes across in assemblies is the right orientation of the part. Design parts in such a way that parts are constrained to locate in the desired orientation.

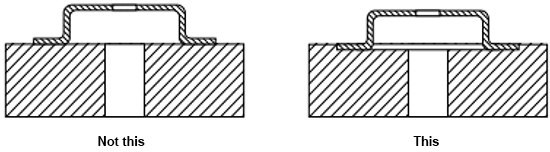

Ease of Location

Designing for Self-alignment of parts must be considered whenever possible.

(Image source)

Ease of Alignment

(Image source)

Inserting fasteners should be made easy without much effort. Components with tapered ends make alignments easier with matching tapered receptacles.

When there is no need for accurate assembly of two parts, make provisions to facilitate quick assembly. In the example on the right, oblong holes in the bracket facilitate quick assembly with the bottom plate.

Ease of Fabrication

Product designers conceive an enclosure design based on component layout, customer’s requirements such as available space, floor standing, or tabletop, etc., He need not necessarily be a sheet metal shop floor specialist with a thorough understanding of machine limitations. For example, the developed sheet dimension of the image shown exceeds available sheet lengths which can be accommodated in the machine. On the other hand, the shopfloor engineer converts the same concepts into a practical solution as shown on the right. The product is split into three parts and welded together for ease of manufacturing. It will be useful to give sufficient thought to the aspects of ease of handling, ease of manufacturing at the design stage.

Fastening Methods

It is important to give particular attention to the type of fasteners required because each one serves a specific function. Also, every fastener has a preferred installation process. It is also important to consider the materials, coatings of the fasteners. Quality versus cost must be weighed properly. Preplanning at the design stage instead of the assembly stage makes a lot of difference.

Besides nuts and screws, there are a wide variety of methods for the purposes of assembly. Screws, nuts, washers, clips, adhesives and sealants, eyebolts, rod ends, straps, gaskets and seals, hinges, levers, handles, pins, spacers, standoffs, springs are all part of the final assembly process. It is important not to miss any detail, however trivial at the design stage.

Welding at the assembly stage cannot be totally ruled out but is to be avoided as far as possible.

(

( (

(