Search

- yohoho

- unblocked games 77

- unblocked games 8

- unblocked games 2

- unblocked games for school

- unblocked games world

- retro bowl

- unblocked games

- unblocked games premium retro bowl college best unblocked games unblocked games

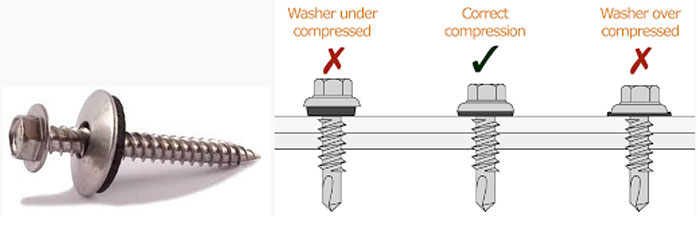

The primary purpose of washers is to distribute the load evenly. They are most often kept between the screw head and the sheet surface or between a nut and the sheet surface to be tightened. Another purpose is to retain the screw in a vertical position with compressive force because screw threads may cut into sheet edge if there is lateral movement of the screw while tightening. Washers may also be used as spacers to fill the gap between the screw head and sheet surface if required.

Some of the commonly used washers are as follows:

Split Washer/Spring Washer. (Image source)

Split Washer/Spring Washer. (Image source)

Plain Washers or flat washers are the most commonly used washers to distribute the load evenly onto the mating surface. The Cup washer has a slightly conical shape which provides an axial force when deformed. A curved washer is curved in only one direction, enabling four-point contacts under pressure. Spring washers have a helix shape and allow the thread to be tightened by the nut in one direction only. Further, the raised edge bites into the underside of the bolt or nut and the part that it is bolted to, thus resisting turning. A serrated washer has radial serrations which bite into softer material to cause a locking washer effect. They also provide effective bonding with electrical grounding components. A tab washer is a locking washer with a side tab that can be bent into place against a nut. A Grommet washer has multiple sharp teeth integrated within a cup washer. These teeth dig into softer materials and remain in place even if the fastener is withdrawn. Damping washers have softer materials to act as dampers against vibrations as well to prevent seepage of liquids.