(Image source)

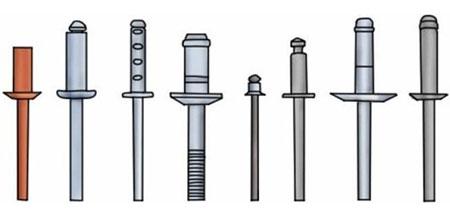

Riveting is a cold process where the force applied causes deformation of a portion of the rivet. The deformed portion forms a bulge and holds firmly the workpieces together like a fastener. Rivets have various designs of the head at one end and they can be solid or hollow. The riveting process required good hole tolerances, positional accuracy and the right type of rivet material. Improperly planned riveting leads to distortion of sheets and other surface blemishes.

Standard upset dimensions.

Standard upset dimensions.1. Blind Rivet

The term Blind rivet comes from the fact that only one side of the workpiece is seen when they are applied. Using predrilled holes two pieces can be fastened together without having to look at the other side. Blind rivets are ideally suited where normal rivets or other joints are not possible. Another advantage is that they are tamper-proof unless destructive forces are applied.

A blind river comprises two parts, the rivet body, and a mandrel. The rivet held by an installation tool is then inserted into the matching holes of two sheets. When the installation tool is triggered, the mandrel pulls the head of the rivet into the blind side of the rivet causing it to bulge and get trapped. The excess length of the mandrel breaks off at a pre-determined break-load. The result is securely held workpieces.

Blind riveting sequence.

Blind riveting sequence.Component Design

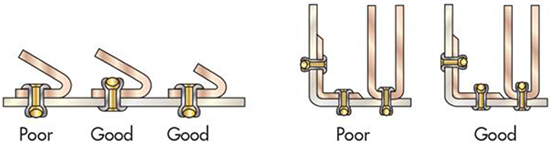

It is very important to plan a blind riveting position in advance while designing a component for the purpose. Easy access to the process is important. Factors such as joint strength, joint thickness, materials, hole size, and head style must be considered before selecting a blind rivet.

Predetermine the access to blind rivet locations

As with solid rivets, blind rivets should not be positioned too close to the edge of a joint subjected to structural loading. The centreline of the rivet hole should be at least equal to the diameter of the rivet.

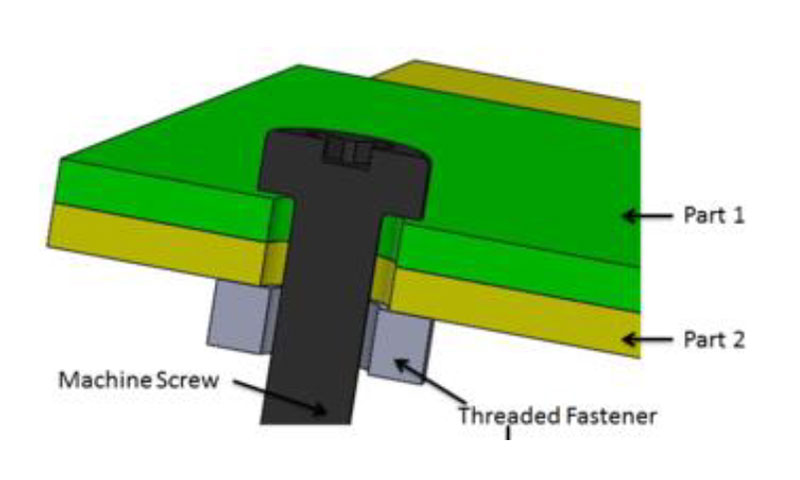

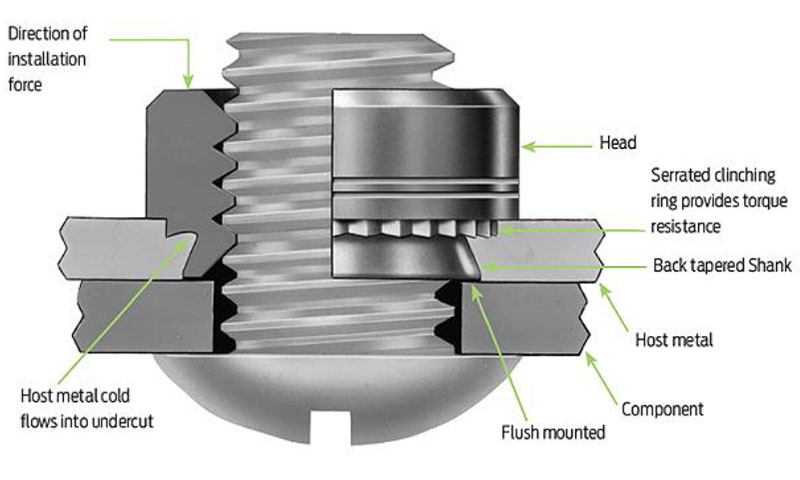

2. Captive Nuts

Normally, a screw and a threaded nut are used in securing two sheets together. At times the location of the nut may not be accessible to fix the screw. In such cases, as in the case of blind rivets, clinch nuts or rivet nuts are used for the purpose. These fasteners will have knurling under the head. As in the case of rivets when compression takes place, the corresponding thickening of the midsection forces the knurling ‘eat’ into the sheet, and clinching takes place. Thus the nuts are securely kept in place permanently.

Clinch nuts and rivet nuts are clinched or rivetted to part 2 to replace conventional threaded nut.

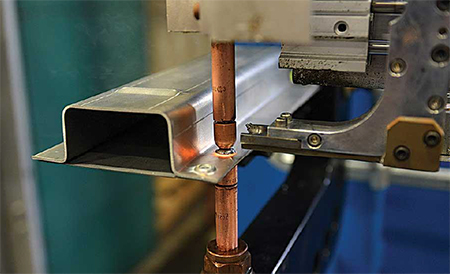

Clinch nuts and rivet nuts are clinched or rivetted to part 2 to replace conventional threaded nut.3. Revit Cum Spot Welding

Rivet cum Spot weld

Arconic Fastenin Sys (Image source)

A hollow rivet may also be spot welded for specific purposes. As can be seen in the picture the sub-assembly is spot welded with hollow rivets. This enables the sub-assembly to get fixed to any other part of the main assemblies with suitable fasteners through the hole available in the rivet.

Typical mistakes in riveting.

Typical mistakes in riveting. Different heads of blind rivets.

Different heads of blind rivets. Clinch Nut.

Clinch Nut. Rivet Nut.

Rivet Nut. Clinch nut nomincalture.

Clinch nut nomincalture.