Design Resource

Terracotta Wall Hangings - Panaji, Goa

Native Handicrafts of Goa

by

Prof. Bibhudutta Baral, Divyadarshan C. S. and Harsha Kulkarni

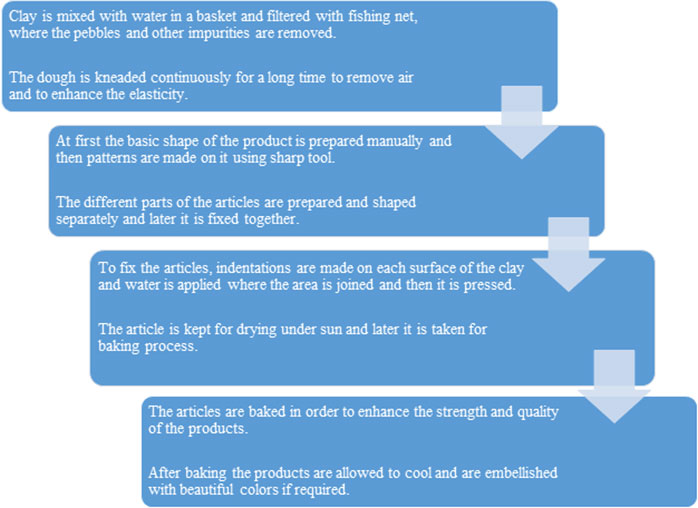

The raw materials are brought from the nearby place which is obtained locally. Initial stage is to refine the clay by removing the dust particles from the clay. The clay is mixed with water in a basket and filtered it using a very fine fishing net, where the impurities and pebbles in the clay will be removed. Later when the clay is dried, it is soaked in water. Finally the dough is pressed or kneaded continuously for a long time to remove the air and to enhance the elasticity. The prepared dough is then used for making products and also it is covered and stored to preserve the moisture.

The parts of the article are prepared, shaped separately and then combined later. Artisan first creates a basic shape of the product and then patterns are made on it using sharp edged metal piece. Artisan creates different parts of coconut tree like trunk, leaves, and shells separately and then it is fixed together. For making leaves, first the small piece of clay is rolled, bent and flattened slowly so that the clay should not develop any cracks. The pattern on the tree and leaves are then made and smoothening of the surface is done by smearing pinch of water.

To combine two surfaces of clay, indentations are made on each surface and water is applied on the place where each clay area joins together and then pressed. Like the same manner other types of wall hangings and decorative items are made. After completion the article is kept for drying under the sun. Later it is taken to furnace for baking process.

This baking process is done to enhance the strength and quality of the products. Here the small articles like decorative items are baked in the furnace. The art pieces are carefully placed in the furnace and it is covered with clay tile pieces to absorb the heat. Wooden pieces are used as fuel in baking process and gradually heat level is increased and temperature is maintained, so that the articles are baked properly.

Depending on the articles and the artisan’s choice of color and strength, the baking process takes place. Small articles are baked for approximately one and half hour and bigger ones takes more than two hours. Later the products are taken out from the furnace carefully and allowed to cool for some time. Under baked and over baked products are not worth in the market.

Finally the products are embellished with beautiful colors if required or else the varnish is applied to give a shiny look to the final products.

Flow Chart: