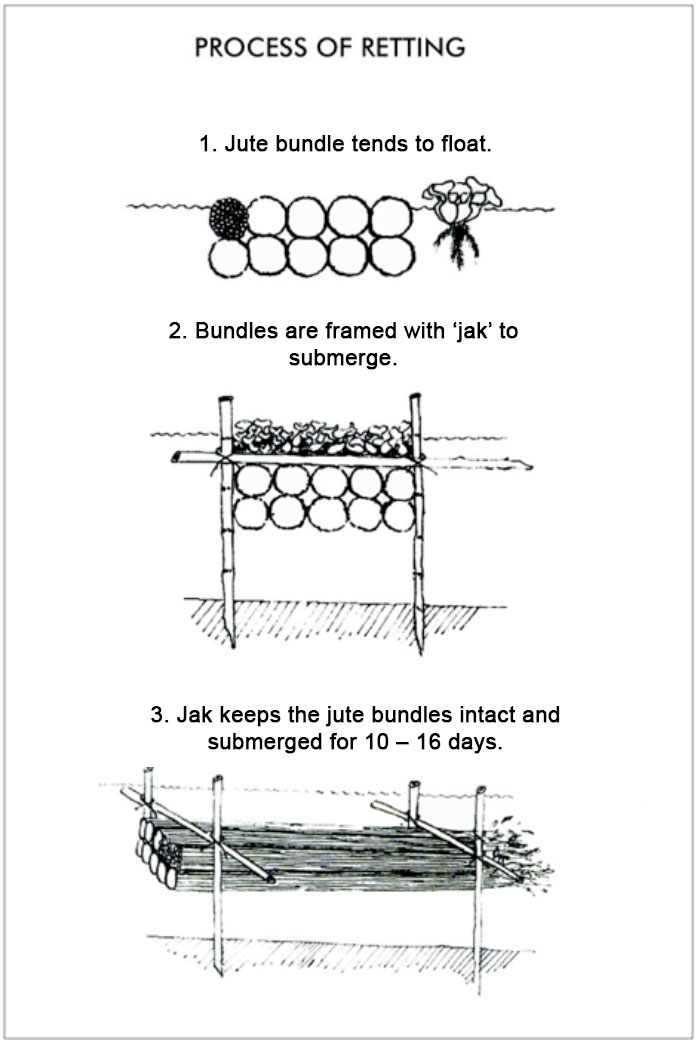

Retting is defined as the process of separating the embedded fiber from the steam through partial rotting by immersion in water; thus rotting is bought by a complex action of microbes naturally present in retting water. After harvesting, jute bundles are brought to the retting site and laid retting in water. The jute bundles normally float on water, thus, these bundles are placed side by side with bottoms all facing in one direction. The second and third layers are overlaid with bottoms facing the reverse direction. These bundles are tied up with two pieces of split bamboos to avoid them from drifting away. This process is called ‘jak’, which prevents it from drifting, and bamboo poles are pushed through the jak into the bottom of the retting channel or tank. To prevent the bundles from floating, they are covered with any easily available tannin-free plant materials such as paddy straws, screwpine leaves, long-leaved grass or sedges, etc., or other logs bamboo are weighted on them. This helps the bundles to submerge 10 cm below the water. The submerging is very important as any portion of the jak or bundle that floats above the water surface will impact the retting process. The jack must remain in the water for 10 to 16 days, depending on the temperature of the retting water. Soft tissues like phloem parenchyma, sieve tubes, companion cells, medullary rays, and cambium rings lie between the wood and bark. When bundles of reed are immersed into water enzymes of aerobic, anaerobic, and facultative bacteria, react to contact with the specific medium on and in the tissues. The initiation of retting depends on the availability of nitrogen substances. The bark of the jute plant, which is freshly cut, can be split loose by splitting fiber from the wood it surrounds. The extraction should be judge by keeping in mind the age of the crop. If over-retted, the fiber becomes fragile and loses in luster. The fiber is ready for extraction only when most of the fiber is found to loosen. The wet stripes of fiber are uncoiled and stretched onto the clean water and washed thoroughly to remove gum, dirt, remains of decomposed plant, and all the retting abide by fiber. In many places, due to the scarcity of clear water, this process is skipped. The good quality of the fiber is directly linked to the accessibility of an abundance of clear water. After the fiber is washed and cleaned, it is necessary to be dried under mild sunlight. The fibers are placed on a bamboo raft and not on the ground as the wet fibers may stick to dust and dirt. These dried fibers will be bundled and tied up, and sent to the factory outlets, where the wholesalers purchase the finished product. Coloured jute is also available, which is coloured with natural and chemical dye colours.

The process of dying jute is very challenging because of its complex chemical component, which requires bleaching and then dyeing it with the preferred colour. Bleaching of jute can be obtained by using sodium persulphate as a peroxygen booster at ambient temperature. The process requires four variables i.e. hydrogen peroxide, sodium hydroxide, sodium silicate, and sodium persulphate, which is enhanced by using the statistical skill, central composite rotatable plan (CCRP). The method involves padding the fiber in the solution using 100% wet pick up and then batching for 2 hours followed by washing. Cellulose is the main element in jute which acts as a dyeing agent for jute fiber, suitable for jute dyeing.

The important conditions to observe are:

- The water must be non-saline and unblemished.

- The capacity of water should be sufficient to let the jute bundles float.

- When the bundles are submerged, they should not touch the bottom.

- The same retting tank or ditch may not be used repetitively, mainly if the water becomes too foul and dirty.