Design Resource

Leharia Tie and Dye - Jaipur

Leharia Tie and Dye, Jaipur

by

Prof. Bibhudutta Baral, Divyadarshan C. S. and Rohit R Chandak

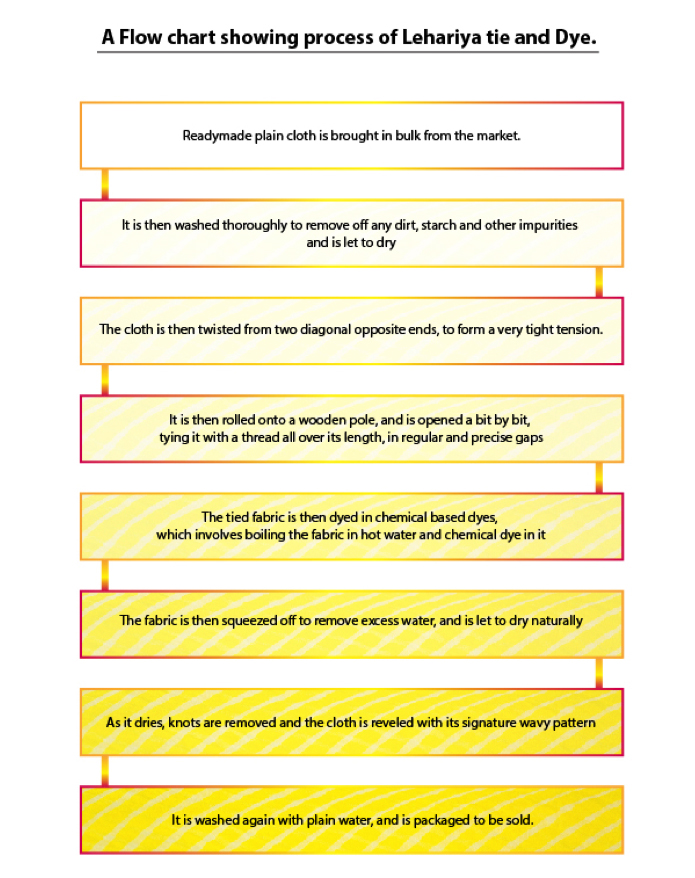

The making process in Leharia involves various simple steps, which are done mainly in backyards of homes or in any free space, by women’s mostly.

Generally, cotton or silk cloth is used for dyeing in this process, the cloth brought from market is washed off to remove any residue such as starch, sand, dirt etc., the wet cloth is then dried for further process, ensuring flawless white piece of cloth. After the cloth is dried, it is twisted with the help of two members, one at either end, it is twisted such that it creates enough tension, and then is transferred onto a wooden stand, consisting of a horizontal table with vertical cylindrical pole, the twisted cloth piece is wrapped around the wooden pole firmly, such that it does not loosen up the carefully done twisting, the wrapped cloth is slowly removed bit by bit and threads are tied to it tightly, which acts as a resisting agent, from dyes. Knotting is done in a precise and regular interval of gap onto the cloth, parallel to each other, which gives cloth its signature waveform kind of a design after dyeing. After the knotting is done, cloth is unwrapped, knotting distance depends on the intricacy of design required, from nearby knotting to knotting with larger distance in between and with more thicker and thinner knotting. After the knotting is completed, the cloth is dipped in water, to make it absorb the further dyeing process, once ensuring the cloth is absorbing water, it is dipped in dye based solution, depending upon the color required and upon the intensity of the color, mostly chemical based dyes are used in the process, dyeing depends on the requirement of the end product, from rainbow colored cloth, which consists of multiple pastel shades of color depicting rainbow, to single color stoles. It is then put to dry as it is with the knots, once dried, the knots are carefully removed, so as not to damage the cloth and is washed for one final time, and is put to dry.

It is then ready to be used as scarf, turban etc.