Organic coatings act as a protective barrier against corrosion and oxidation. These coatings are applied to the surface of sheets for protection from oxidation and rusting as well as for appearance. Organic coatings are chemically inert and impermeable. Organic coatings can be paint or powder-based. Painting is relatively a simpler process as compared to powder coating. But solvent-based paints emit volatile compounds while powder coating does not emit such compounds. Powder coating can be more durable than paint. The sequence in which the painting or powder coating process is carried out is as follows.

- Surface Preparation

- Application

- Protection

1. Surface Preparation

This is an area most ignored and given less priority. Blemishes on the metal surface will be damaging to the applied finish and sometimes they even appear magnified after finishing. Therefore, thorough surface preparation is the key to good finish and longevity. Then the desired finish is given by way of painting, powder coating, plating, or some other chemical processes. Normally a protective layer is given over the finished surface.

Sheet metal or for that matter any material surface needs surface preparation before being carried on to be given desired finishes. There are set procedures for surface preparation, but it also is an activity requiring good manual skills.

The surface may have dents, crests, rust, or other deformities. They need to be addressed and removed to move the job to the next stage of finishing.

2. Mechanical Cleaning

The surface of the parts must first be cleaned mechanically. It can be simple wiping with a clean cloth if the surface is without blemishes or it may require the use of mechanical aids such as steel wool, abrasive papers, and brushes and wire brushes to remove dirt, rust, and caked foreign material. Non-metallic bristles provide milder abrasive action. Heavy wire brushes provide strong action. The parts are wiped clean with solvents after mechanical cleaning.

Abrasive papers and brushes. (Image source)

For large size parts and production line quantities abrasive blasting is adapted. This involves bombarding the part with high-velocity abrasive materials such as sand, aluminium oxide, silicon carbide, plastic granules, steel balls, etc., all depending upon the level of scales and corrosion on the surface of the metal part.

Sand Blasting. (Image source)

Sand Blasting. (Image source) Shot Blasting. (Image source)

Shot Blasting. (Image source)The quality of a paint coat or plating surface is directly proportional to the thoroughness of the surface finish.

3.Chemical Cleaning

After proper mechanical surface cleaning, the next step is to give a conversion coating to the surface of the substrate. Conversion coatings involve changes to the chemistry of the metal itself. They can be used to provide corrosion resistance, enhanced appearance, or act as a primer coat for paint.

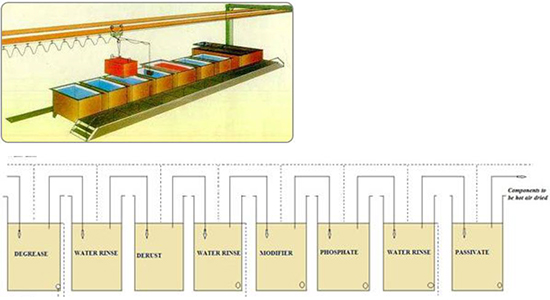

Pre-Treatment process for steel sheet products

Seven Tank Process

A "7-tank process" is a process where parts are immersed in seven tanks sequentially. Normally, a zinc phosphating process is done in 7 steps while the simpler iron phosphating pre-treatment process is done in 3 steps or sometimes 5 steps.

The steps are as follows:

- De Greasing

- Rinsing

- De Rusting

- Rinsing

- Phosphating

- Rinsing

- Sealing

(Image source)

The seven tank pretreatment line

1. Degreasing - Alkaline degreasing for 5-7 minutes at about 70 deg C to remove oils and grease.

2. Water Rinsing - Water rinsing for removal of traces of alkaline.

3. Derusting - Acid derusting normally by diluted sulphuric acid derivate solution for 5- 15 minutes at room temperature to remove rust.

4. Water Rinsing - Water rinsing to remove traces of acid. Any traces will cause rusting on steel parts.

5. Phosphae Conversion - Coating of zinc phosphate or Iron phosphate for 5-15 minutes depending upon temperature up to 70 deg C, onto the metal surface to an extent of 80 – 100 microns.

6. Water Rinsing

A car body under pre treatment.

A car body under pre treatment. A mini PLC controlled 7 tank process. (Image source)

A mini PLC controlled 7 tank process. (Image source)7. Passivation - Passivation to remove any embedded contaminants and return the part to its original corrosion specifications.

3 in1 Solutions

(Image source)

There are also inexpensive 3 in 1 solutions available mainly for steel and iron surface cleaning. These contain a mixture of alkaline, acidic and phosphate compounds which form iron phosphate coating on the surface. The metal surface was wiped clean with these solutions. These are adequate in many small production operations provided the process is done with due care.

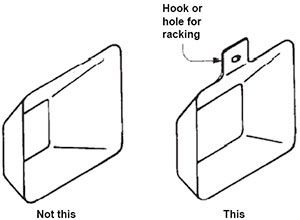

Design Consideration

Example

The design of components should permit the flow of cleaning solutions to reach all corners. They also need to be designed for hanging to a hook so that the component is not held manually. There are areas such as crevices, folds, hems, etc., where cleaning solutions may get trapped. While it is not entirely possible to avoid such mechanical details, care must be taken to minimize entrapments or make provisions for draining out the solutions.

Pre-Treatment process for non-ferrous products

Chromate Conversion Coatings

Chromate conversion coatings are obtained by chemical reaction with the substrate to form chromate film over the surface. The coating adheres to the metal at a molecular level and hence good binding. It creates an iridescent yellow-green film that resists corrosion, can be used as a primer for paint and retains electrical conductivity. The process can be by dipping or spraying.