The following explanation though somewhat technical to a non-engineering student is useful to understand the science behind the physical properties of materials. This will help in converting a design idea into a practical solution.

The differences between stiffness and strength in metal:

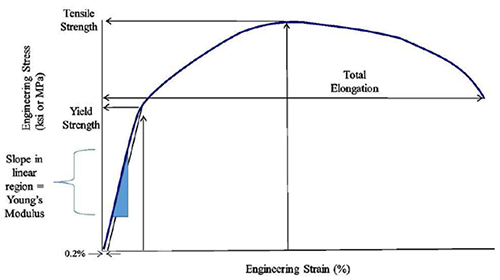

Stress Strain Diagram (Image source)

Strength

Strength is a measure of the stress that can be applied to a material before it permanently deforms (yield strength) or breaks (tensile strength). If the applied stress is less than the yield strength, the material returns to its original shape when the stress is removed. If the applied stress exceeds the yield strength, plastic or permanent deformation occurs, and the material can no longer return to its original shape once the load is removed when the applied stresses are higher than the material’s tensile strength, the material cracks when forming.

Stiffness

Stiffness relates to how a component bends under load while still returning to its original shape once the load is removed. Since the component dimensions are unchanged after a load is removed, stiffness is associated with elastic deformation. The stiffness of a component is a function of both material and geometry.

Altering a flat surface geometry increases its rigidity. A piece of paper is flimsy, but putting a crease down its center makes it more rigid. Darts, beads, and ribs are shapes that can be added to parts to restrict flexing. On surface parts visible to the consumer, they are called feature lines or character lines, highlighted for their aesthetic benefits.

Ribs are added to truck bed designs to help increase overall stiffness.

(Image source)

For instance, the panels that comprise a pickup truck bed shown above are mainly flat. Ribs are incorporated to help increase overall stiffness. However, the sheet metal needs to be sufficiently formable to accommodate the additional shapes. The truck bed panel ribs might not be very deep, but the metal needs to be stretched over short distances.