Hemming and seaming are two similar metalworking processes in which a sheet metal edge is rolled over onto itself. Hemming is the process in which the edge is rolled flush to itself, while a seam joins the edges of two materials.

1. Hemming

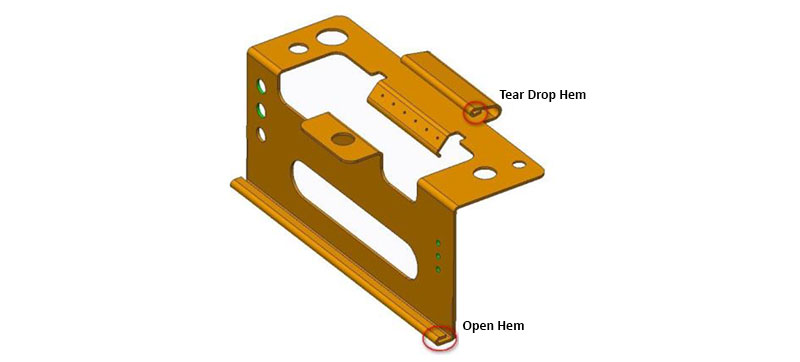

Hemming on an automobile part.

Hemming on an automobile part.

The accuracy of the hemming operation is particularly important since it affects the appearance of the surface and surface quality. Improperly done hemming causes dimensional variations and material deformations such as wrinkles in the flange.

Desktop Seamer.

Desktop Seamer.