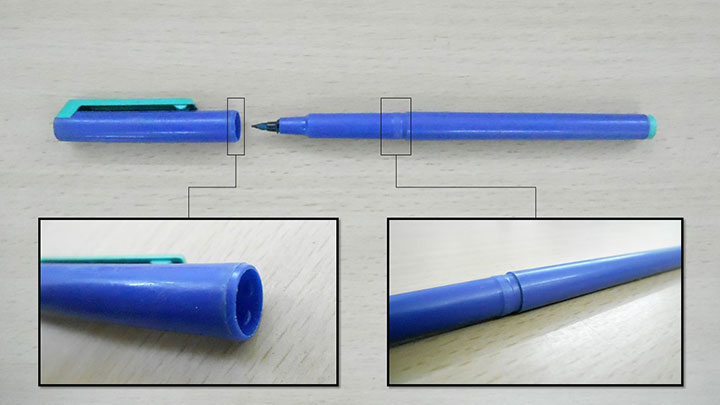

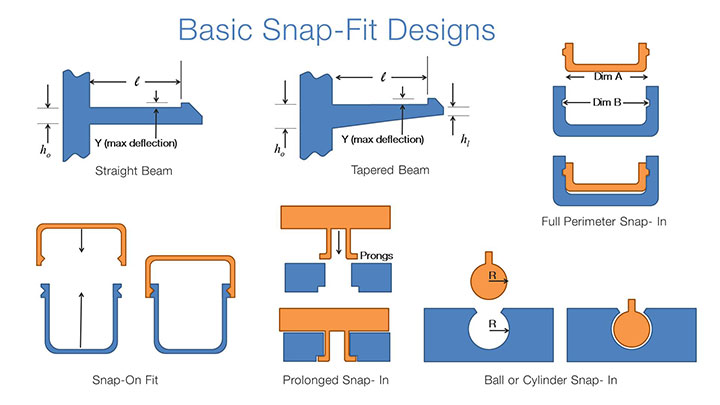

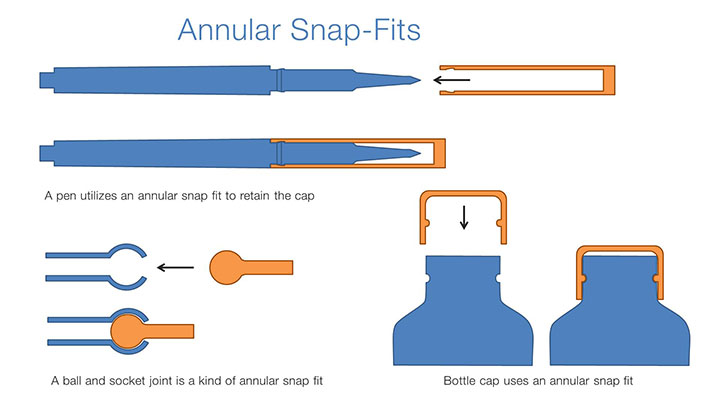

Snap fits are most economical and rapid methods of assembly for high volume production. Snap-fits may be a detachable or a non-detachable joint. All snap-fit designs consist of two basic parts. First one is a flexible member which is acting like a cantilever which bends and returns to its original position during snapping action. The second member holds the cantilever having sufficient space to accommodate the flexing of cantilever. Snap-fits can be broadly categorized as cantilever snap-arms and annular snap joint. The shape of the undercut determines whether the joint can be separated or not. Snap-fits with angled undercut can be disassembled easily. Snap-fit provide both secure as well as easy assembly of the parts. They facilitate easy and quick detachment of electrical components for repair.

Design considerations